Madurai

Rice mills, which largely relied on manpower 25 years ago, were initially located on Kamarajar Salai, Mahalipatti and Keerathurai in Madurai. But owing to residentialisation in those areas, they moved to Chinthamani.

Before the mechanisation, about 40 to 60 workers were required in a unit for manual operations that included hulling, boiling, packaging and loading. Now, it has reduced to less than 10, with workers only needed for loading and packaging. Mostly, migrant labourers from Bihar and Odisha are engaged in these tasks.

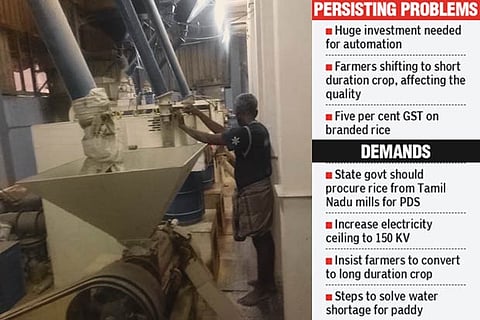

Since 2000, many rice mills have upgraded to the automated system to produce white rice. While this came in handy to offset the problem of labour shortage, the expensive technology drove several rice mills out of business. It requires from Rs 6 crore to Rs 8 crore to set up a mechanised unit and only deep pockets managed to shift successfully.

Nearly 120 rice mills were in operation five years ago. Now, it has been reduced by half as many mill owners could not manage to gather funds, said K Rajendran, general secretary of Madurai District Rice Mill Owners’ Association.

The decrease in the cultivation of paddy has also worked adversely for the farmers. Paddy cultivation is largely influenced by the water supply. As access to water for paddy fields reduced, many farmers were forced to cultivate short duration crops, which has span of 100 to 120 days. However, it failed to yield desired results as the quality of the rice dropped.

In the long duration paddy crop, which is cultivated in a span of 135 to 150 days, the quality was guaranteed. Nowadays, the consumers are more concerned about the quality than the price. The state government should insist farmers to cultivate the long duration paddy crop, following the example of Karnataka and Andhra Pradesh.

To ward off water crisis, the government should think of long-term solutions, including interlinking major rivers across India and construction of check dams to prevent flow of surplus water into sea.

The rice mills and its stakeholders suffered a major setback when Tamil Nadu government started procuring rice, which is meant for the Public Distribution System, from Karnataka and Andhra Pradesh. To help the mills, which are facing a crisis, the State government should come out with a policy decision to procure rice only from Tamil Nadu. The move will benefit both paddy farmers and rice millers, Rajendran told DT Next on Sunday.

K Vasanthavel, president of the association, said overhead cost, which largely includes electricity, were not in line with requirements. When the state experienced acute power crisis before 2011, the rice mill processing units, which come under Micro, Small and Medium Enterprises (MSME), were exempted from the power cuts then.

Referring to rice processing cycle, which consumes a considerable amount of electricity, he said initially the machinery would remove dust and destone paddy. Subsequently, paddy would be soaked before pressurising it to rise the boiling temperature of water using the high pressure steam. Then, it would be dried up and moved to the storage bin. Finally, the hulls and barns from paddy grains to produce polished rice. Rice produced in Madurai is sent Sivakasi, Tirunelveli, Tenkasi, Nagercoil and also to Kerala, he said.

Currently, the State Load Despatch Centre fixed a maximum ceiling of 112 KV for a mechanized rice mill unit. The electricity consumption is growing and it requires about 140 to 150 KV of electricity to run a unit, said K Anandavel, joint secretary of the Madurai District Rice Mill Owners’ Association. So, the association has demanded the government to increase the ceiling to 150 KV.

The mechanised rice millers, for whom operations exist only for a period of four months in a calendar year, after every harvest season, had been asked to move to high tension power lines.

To make matters worse, the five per cent Goods and Service Tax (GST) on registered rice brands has caused uncertainty in the market. Capitalising on the situation, tax evaders market misbranded their products giving tough competition to brand builders.

While the government continues to insist on safe food handling with hygiene and other essential factors such as registration of brand, date of manufacturing, quantity, address of manufacturer and maximum retail price to be labelled on rice bags as required by the Food Safety and Standards Authority of India, there are no checks to ensure that these aspects are followed, the joint secretary added.

Visit news.dtnext.in to explore our interactive epaper!

Download the DT Next app for more exciting features!

Click here for iOS

Click here for Android